Food & Beverage Manufacturing Wastewater Treatment Solutions

Food and beverage manufacturing generates wastewater that may push past what municipal systems are designed to treat without pretreatment support. The volumes are high and the organic loads are intense, with pH swinging wildly depending on what’s being processed and whether sanitation is mid-cycle. The regulatory framework requires navigating multiple overlapping authorities simultaneously: FDA requirements, EPA pretreatment standards, and local sewer district limits that vary by jurisdiction and rarely agree with each other.

Getting wastewater treatment wrong creates problems that cascade: discharge violations, sewer surcharges eating into margins, and production slowdowns that ripple through the schedule. Facilities that run smoothly have learned to manage their wastewater as a core operational function, not an afterthought, because proper treatment protects both the operation and the environment it’s part of.

Understanding Food & Beverage Wastewater

Municipal treatment plants are designed around domestic sewage as their baseline. What comes out of a food processing facility carries significantly higher organic loads, wider pH variability, and more unpredictable flow patterns than that baseline accounts for.

Processing operations generate the bulk of it: washing raw materials, cooking, cooling, and packaging. These all produce water heavy with organic matter and the composition shifts based on what’s running through the line that day. Cleaning and sanitation add another layer: CIP (clean-in-place) systems, floor washing, and equipment sanitization contribute significant volumes with variable chemical composition, including the caustic and acidic agents that make pH so unpredictable. Cooling systems bring their own contribution, potentially picking up lubricants and other contaminants from the processing equipment they serve.

What makes food and beverage wastewater distinctive is how these characteristics combine. Biochemical oxygen demand (BOD) and chemical oxygen demand (COD) run extremely high compared to municipal wastewater. Organic solids create loading issues that accumulate over time and pH can fluctuate from acidic to alkaline shift as products move through the line and cleaning chemicals cycle through the system.

Volume compounds the challenge when peak flows during washdowns and shift changes can overwhelm systems sized for average conditions. A facility might discharge relatively little during production hours and then release a surge when sanitation crews come through. Any treatment program built around averages can fail at the moments that matter most.

Regulatory Requirements for Food & Beverage Facilities

There are two sets of rules, often different in their specifics, and businesses are responsible to make sure they meet them. That’s the regulatory reality for food and beverage facilities managing wastewater discharge.

Federal pretreatment standards from the EPA establish baseline requirements for what can be discharged into publicly owned treatment works (POTWs). These standards exist because industrial-strength discharge at the concentrations food processing generates can overwhelm municipal treatment processes without intervention. High BOD loads can overload biological treatment, solids can accumulate in sewer lines and pH extremes damage infrastructure and kill the microorganisms that make treatment work.

Local sewer districts typically impose limits stricter than the federal floor, with BOD caps in the form of total suspended solids (TSS) limits. Discharge permits that specify monitoring requirements, sampling frequencies, and reporting obligations are needed for local sewer districts. The specifics depend entirely on your local authority, which means a facility in one jurisdiction can face different limits than an identical operation twenty miles away.

The penalties for non-compliance go beyond fines. Repeated violations can trigger increased monitoring requirements, mandatory pretreatment system installation, or revocation of the discharge permit entirely. Some facilities have faced production shutdowns when their discharge problems became severe enough to threaten the POTW’s own compliance.

Crystal Clean works within this regulatory framework with documentation and reporting support built into the service relationship. When discharge characteristics shift because of a new product line, seasonal production changes, or tightening local limits, having a partner who understands both the technical treatment side and the regulatory reporting side turns those adjustments into operational transitions, avoiding compliance crises.

Treatment Solutions for Common Challenges

What works for one waste stream won’t always work for another. The treatment approach has to address each challenge on its own terms while accounting for how they interact in your facility.

High-Strength Organic Waste

The BOD and COD levels in food processing wastewater routinely exceed what sewer districts will accept without pretreatment or surcharges. A dairy operation or brewery can easily generate wastewater with BOD levels 10 to 20 times higher than domestic sewage. At those concentrations, discharging without pretreatment risks overwhelming your local POTW’s biological processes and triggering surcharges or violations.

Reducing organic loading requires either on-site pretreatment or removal of high-strength waste streams before they enter the sewer system. There are several options, such as biological treatment that uses microorganisms to break down organic matter or chemical treatments which can precipitate solids and reduce loading. The right approach depends on your waste characteristics, volumes, and local discharge limits.

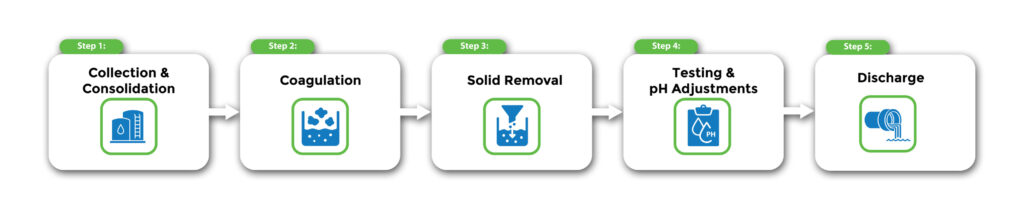

Crystal Clean has a wastewater management program which can remove high-strength liquid waste streams via vacuum truck for off-site treatment at Crystal Clean’s own permitted treatment facilities. This reduces the organic load in your discharge and shifts the treatment burden to facilities specifically designed and permitted to handle it.

pH Control and Neutralization

Food processing involves acids and bases that create pH swings in wastewater throughout the day. Things like, citric acid from fruit processing, caustic cleaners from CIP systems, the discharge might be acidic one hour and alkaline the next, depending on where you are in the production and sanitation cycle.

Sewer systems cap pH for good reason. Extreme levels damage pipes, disrupt treatment biology, and can release toxic gases in confined spaces. Facilities need either equalization basins to blend flows and moderate pH, or active neutralization systems that adjust pH before discharge.

For batches of strongly acidic or alkaline wastewater that can’t be safely neutralized and discharged on-site, Crystal Clean’s vacuum truck services remove them for proper treatment at permitted facilities, keeping your discharge within limits without the risk and complexity of attempting on-site neutralization.

Solids Separation and Sludge Removal

Removal options include screens, settling tanks, and clarifiers to capture organic solids before they reach the sewer system. These systems work continuously until the solids accumulate to the point where they need removal, and they lose effectiveness gradually enough that the decline isn’t always obvious until discharge numbers start climbing.

The material that accumulates is typically a liquid or semi-solid slurry rather than dry solids. Crystal Clean’s vacuum trucks handle these applications. We remove accumulated sludge from settling tanks and clarifiers, transporting it for proper treatment, and restoring the system to full capacity. This applies to liquid and sludge waste streams; food solids that are managed separately require containerized disposal.

Every food and beverage operation is different. What a beverage producer generates looks nothing like what comes out of a meat processing line. Seasonal operations create spikes and lulls that year-round facilities never see. Crystal Clean builds custom treatment programs around each facility’s reality rather than applying a template that fits no one well.

Facility Storage Space is Running Short

Liquid waste consumes more floor space than the drums themselves. Secondary containment takes square footage, spill response clearance takes additional space for safety protocols, and positioning decisions must account for worst-case scenarios.

Then there’s the safety dimension. Liquid waste accumulation creates slip hazards around storage areas, drum failures or leaks expose workers to materials they shouldn’t come into contact with, or fumes can accumulate in enclosed spaces. The longer liquid waste sits, the more these risks compound. Facility managers who track inventory, manage traffic flow, and plan emergency response all have to work around the liquid waste footprint.

Crystal Clean offers reliable, flexible pickup scheduling for liquid wastes, so waste moves out on a timeline that works for operations rather than racing against storage capacity or containment limits. This helps your facility become cleaner, more organized, and safer to navigate.

Choosing the Right Treatment Partner

Call a general waste services company about food processing wastewater, and you might come away with more questions than answers. The contaminants are different, the regulatory framework involves food safety considerations alongside environmental compliance. Production schedules and sanitation requirements create operational rhythms that differ significantly from standard industrial facilities.

Industry expertise matters here. A partner who understands the connection between your sanitation schedule and your wastewater profile can anticipate problems a generalist might miss. That understanding comes from working inside food and beverage operations, not from reading about them.

24/7 availability isn’t optional. When your separator backs up or your settling tank overloads, sanitation stops. When sanitation stops, production stops. Response time in food and beverage processing carries a cost that it simply doesn’t in a facility running one shift with no food safety obligations.

Fleet capabilities need to match the work. Routine separator maintenance needs a smaller vacuum truck unit. Tank cleanouts and sludge removal need more capacity. A provider handling food and beverage facilities needs both, plus the flexibility to handle scheduled service and emergency calls with the same level of expertise.

Where does the waste go? Crystal Clean operates its own regional wastewater treatment facilities designed to treat industrial waste streams. Discharge from these facilities meets EPA, state, and POTW standards. Manifests, service records, and treatment verification create the chain of custody that proves proper handling when auditors or regulators come through.

Partner With Crystal Clean

Between organic loading, pH volatility, solids accumulation, and discharge limits that vary by jurisdiction, food and beverage facilities carry a wastewater burden that most industries never have to think about. Managing all of it simultaneously while keeping production moving is the job.

Crystal Clean handles vacuum services, treatment at our own permitted facilities, and compliance documentation under one program. Scheduled service prevents problems. Emergency response addresses them when prevention falls short. And complete documentation means you’re ready when auditors arrive, not scrambling to reconstruct a paper trail.

Your operation deserves a partner who doesn’t need the twenty-minute explanation.

Contact Crystal Clean for a free waste assessment. Our team will evaluate your waste streams and recommend the right solidification approach for your operation.