Dedicated to Sustainability & Corporate Social Responsibility

Sustainability Reporting

Crystal Clean’s vision is to protect the Earth’s resources by helping the business world run cleaner. To us, sustainability is more than a simple checkbox on a list of practices. It is part of who we are as a company. As an environmental services provider, we have a responsibility to sustainably manage the material we collect. Crystal Clean realizes that creating a successful business and building a better world are not conflicting goals – they are both essential for long-term growth that benefits our employees, customers, and the communities where we live and work.

Crystal Clean’s sustainability report documents our journey as we continue to grow our mindset of sustainability. We are committed to evaluating ways to improve our Environmental, Social, & Corporate Governance (ESG) practices, and we will focus on the ways we can build a better world.

Previous Sustainability Report Editions

Waste Life Cycles

Crystal Clean has always been a sustainable company by virtue of the environmental services it provides to its communities and customers. Our business’s core value is in reusing, recycling, and re-refining materials which are put back into the supply chain.

Our commitment to sustainability begins with the waste materials we collect. Whenever possible, the waste will be recycled, reused, or implemented in a waste-to-energy process. By providing premier, sustainable, and cost-effective services, we continue to protect the earth’s resources and help the business world run cleaner.

In pursuit of this goal, we have invested in developing multiple waste recovery centers around the nation, including an oil re-refinery, regional antifreeze recovery centers, and several wastewater treatment facilities. Our waste life cycles benefit not only our own sustainability initiatives, but those of our customers as well.

Oil Services

Crystal Clean’s used oil collection service offers scheduled, safe, and environmentally sound removal of used oil and oily water. The vast majority of the oil collected is sent to Crystal Clean’s state-of-the-art oil re-refinery to be re-refined into high-quality Group II base oils, co-product fuels, and vacuum tower asphalt extender. Our re-refinery is permitted to process up to 75 million gallons of used oil per year and contains a specialized laboratory to ensure our re-refined oil meets or exceeds industry standards. The remaining oil we collect is disposed at one of our several oil depots in a waste-to-energy program.

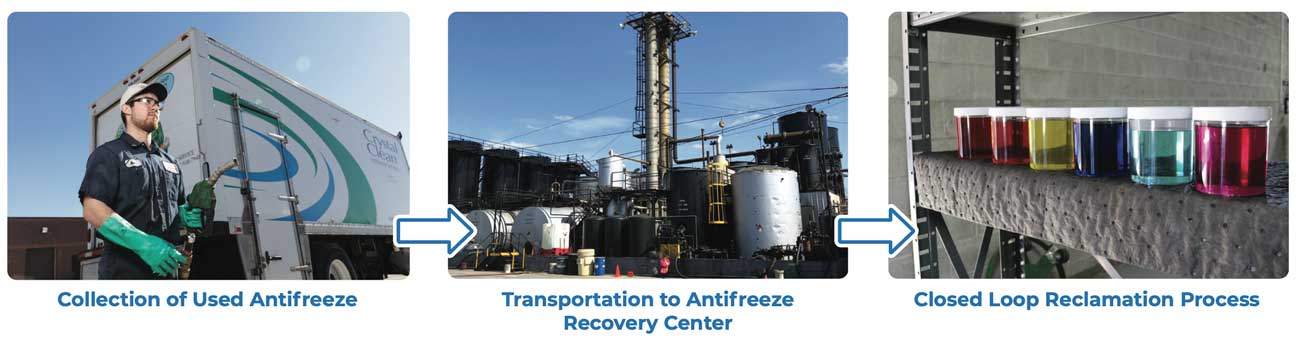

Antifreeze Services

Crystal Clean’s antifreeze recovery service provides environmentally responsible recovery and delivery of bulk premium automotive and heavy-duty antifreeze and heat transfer products. Used antifreeze is collected and sent to one of our regionally located antifreeze recovery centers. At the recovery center, used antifreeze goes through a pretreatment and distillation process. The distilled glycol is reclaimed into a 50/50 antifreeze blend, creating a closed loop reclamation process. The distillation bottoms are properly managed through a waste-to-energy process or secure landfill disposal.

Waste Water (Vacuum Truck Services)

Crystal Clean’s vacuum truck service program is a state-of-the-art waste water management program that helps both large and small quantity generators manage their waste water and related solids with a service that is focused on each customer’s specific need, such as oil-water separator clean out. Vacuum trucks collect waste water, oil, and solid waste from customer locations and transport the waste to one of Crystal Clean’s properly permitted waste water treatment facilities (WWTF). Vacuum waste collected outside of a Crystal Clean WWTF network is sent to an audited 3rd party processor. The waste water is processed to remove oils, solids, and other contaminants leaving the clean water for discharge. The clean water is discharged to a publicly owned treatment works (POTW) to be further treated and discharged. The consolidated, stabilized solids are sent to properly permitted, secure landfill disposal.

Parts Cleaning

Crystal Clean’s parts cleaning service uses aqueous and solvent solutions for cleaning, and Crystal Clean manages the recycling or treatment of residual cleaning solutions. Used solvent solutions are gathered in bulk and then reclaimed to be recycled and remanufactured into new solvent solution. Our low flash solvent is separated and sold into a re-use program for non-land applied construction materials. Used aqueous solutions are gathered in bulk for separation. The oil found in the used aqueous solution is reclaimed for re-refining. If the oil is unsuitable for re-refining it is disposed of in a waste-to-energy process. The remaining used aqueous solution is sent to a waste water treatment facility to be processed to meet POTW standards for discharge.

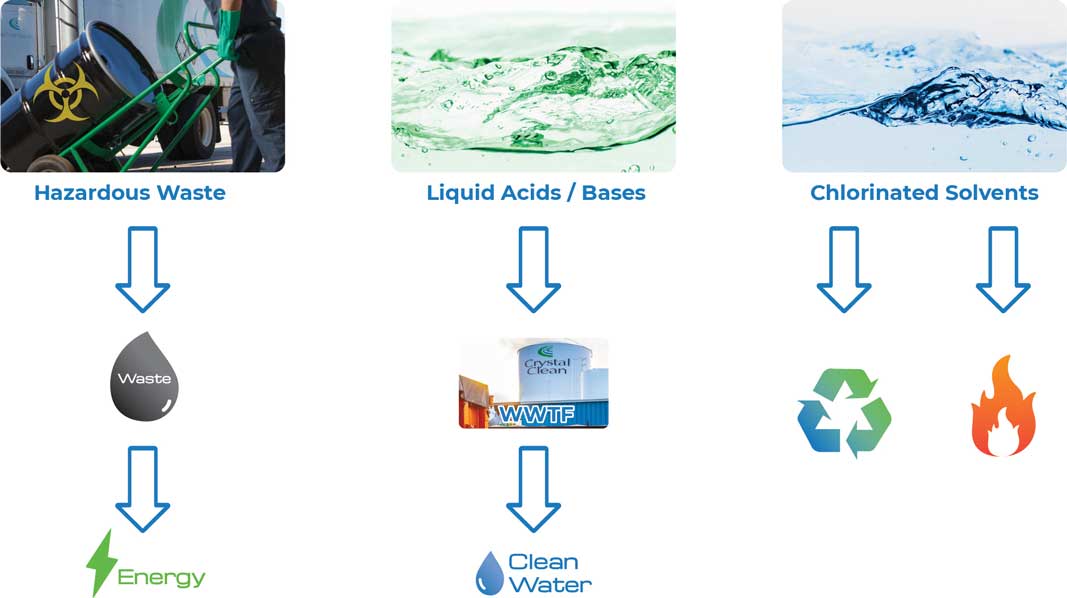

Hazardous Waste

Hazardous waste requires the most care during disposal, and Crystal Clean follows specific disposal methods depending on the type of hazardous waste. This process begins with collection and transportation to a properly permitted treatment or disposal facility. Whenever possible, hazardous waste will be managed by recycling in a waste-to-energy fashion. It will either be formulated into fuels for other manufacturing processes or left as-is for use as supplemental fuel. If the waste has no fuel value, it may be incinerated or landfilled. Liquid acids and bases are sent to a WWTF for contaminate filtration and treatment, and upon meeting standards are sent to a POTW for discharge back into waterways. Chlorinated solvents will be reclaimed into a new product or sent for incineration. Hazardous waste which cannot be safely recycled is properly disposed in a fully permitted Subtitle D landfill.

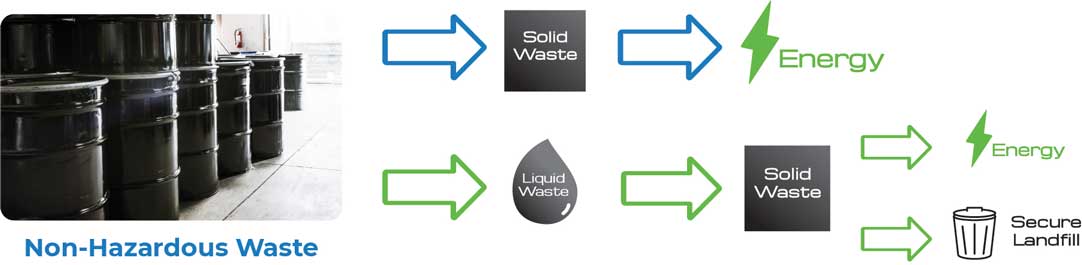

Non-Hazardous Waste

Non-hazardous waste is collected and disposed of in two methods depending on its state of matter. Solid non-hazardous waste is typically disposed through a sustainable waste-to-energy process. Liquid non-hazardous waste is solidified and prepared for a waste-to-energy process or secure landfill disposal.

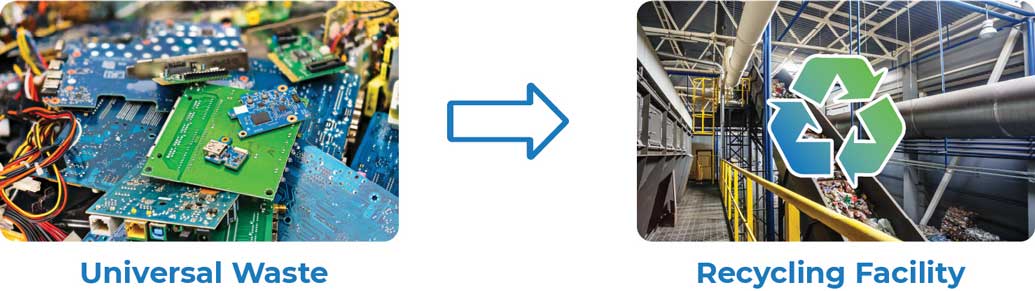

Universal Waste

Universal wastes are common items that can be found almost anywhere. Universal wastes may include bulbs, batteries, and electronic scrap. Crystal Clean collects these wastes and transports them to a recycling facility, where they undergo a reclamation process that allows their elements to be reused.

Absorbents & Non-Hazardous Solids

Absorbents are used to contain oils and other chemicals during a spill. Secondary containments are used to contain larger leaks and spills from drums, totes and liquid storage containers. Used absorbents are disposed of in a waste-to-energy process whenever possible. If the waste has no reusability, then it is solidified and sent to a landfill for secure disposal. Sumped containment waste is handled based on its criteria of hazardous or non-hazardous waste.

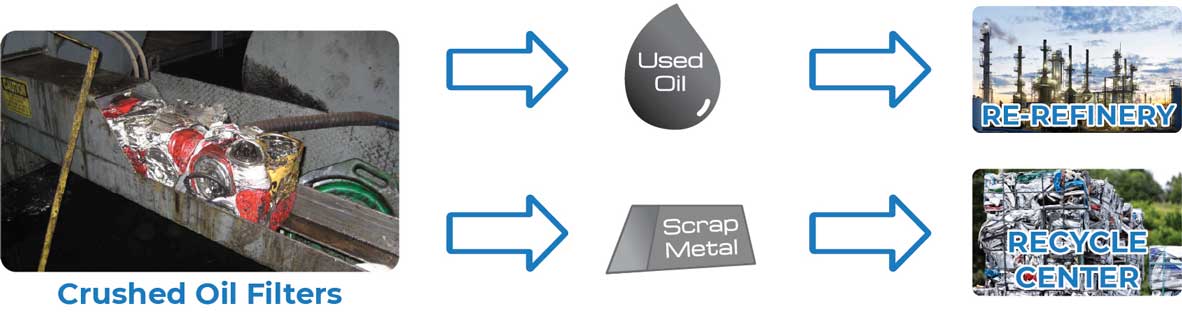

Oil Filters

Used oil filters are collected and sent to a company owned or third-party oil filter processing plant for processing. The filters are crushed to separate the used oil and scrap metal. The used oil is sent to Crystal Clean’s oil re-refinery and scrap metal is sent to a recycling center to be made into steel products.