Optimized Fluid Use

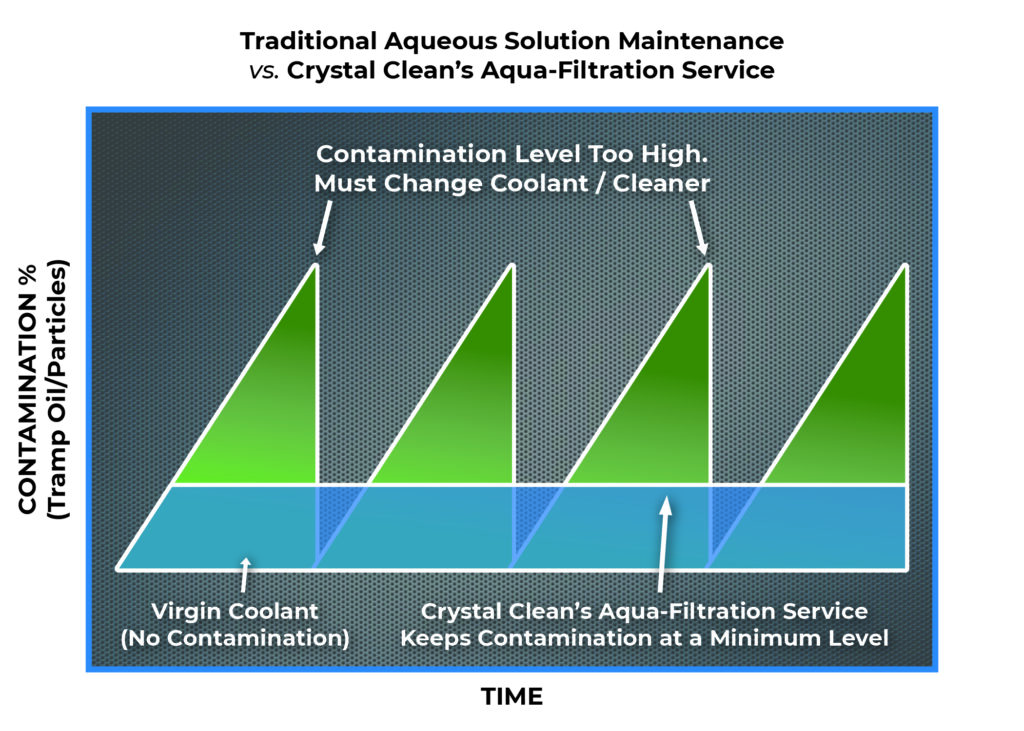

Crystal Clean’s innovative Aqua Filtration System is developed to extend the life of water-based fluids and coolants used in a variety of industrial applications. This results in minimized down-time, improved product finish, lowered cost of maintenance, waste minimization, and more. The advanced technology utilized by the AFS prolongs the life of machines which use it, as well as reduces bacteria and odors.

The patented filtration system technology utilizes the oil attracting properties of the fluid concentrate to carry the contaminant oils away from the process into the AFS unit. The AFS unit strips away the contaminants from the fluid into a separate container for easy removal and treatment. This fully automated machine requires no operator attention and contributes to your environmental sustainability efforts.

The Aqua Filtration System is designed for any operation that requires the use or filtration of an aqueous fluid. Possible applications include aqueous parts cleaners, machine coolant sumps, air compressors, CNC machining, mop water stations, and more.

Aqueous Chemistry Filtration

Develop Cost Savings Through a Constant Recycling of Chemistries to Increase Your Business’s Sustainability.

Machine Cutting Coolant

Machine cutting coolant often totals a considerable expense. Extend its life and efficiency through the utilization of aqua filtration.

Air Compressor Condensate

Stop regulated condensate from being a part of your waste stream. Properly Collect and Dispose of Air Compressor Condensate Via Aqua Filtration.