Renewable Resources Created from Used Oil

Crystal Clean’s state-of-the-art oil re-refinery in Indianapolis, IN is permitted to process up to 75 million gallons of used oil per year. The used oil is transformed into our three primary re-refinery products: high-quality Group II base oils, vacuum tower asphalt extender (VTAE), and hydrotreated low sulfur fuel oil (HT-LS).

Our HCC 150 Group II base oil, when formulated with additives from any of the major additive producers, exceeds the latest industry standards: API SP and ILSAC GF-6 for passenger car motor oils, and API CK-4/SM for heavy duty engine oils. On average, we produce 3,000 barrels of Group II base oils each day, 20,000 barrels of vacuum tower asphalt extender each month, and 9,000 barrels of hydrotreated low sulfur fuel oil each month.

Our re-refined oil products go through rigorous laboratory testing to ensure it meets or exceeds API and ILSAC industry standards. All base oil products we produce are well suited for a wide variety of automotive, industrial, and marine lubricants, as well as diluents for additives and process oil applications. In all of our endeavors, we give the highest priority to understanding and satisfying the unique requirements of each individual customer. Our attention to detail ensures that our customer base receives on-specification, high quality lubricant base oil for blending API Licensed automotive and other industrial finished products.

Reduce Your GHG Footprint With Crystal Clean Re-Refined Base Oils

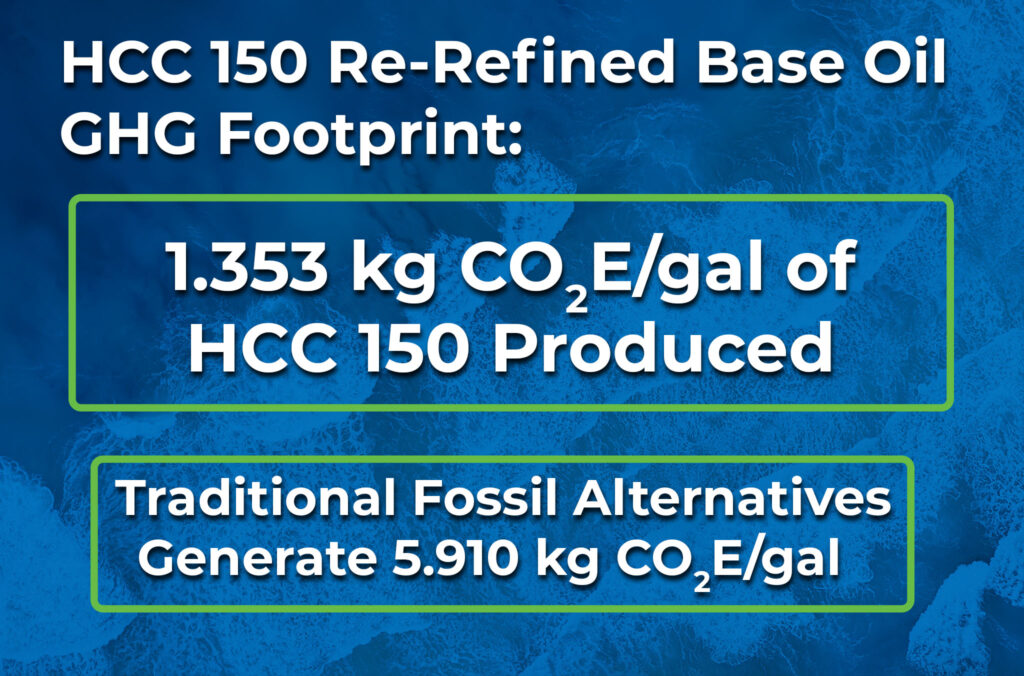

Crystal Clean’s re-refined base oil transforms oil into a renewable resource, giving you a reliable product that brings together high-quality performance and proven greenhouse gas reduction benefits. In a study by environmental consulting firm ClimeCo, commissioned by Crystal Clean and critically reviewed by and independent third-party, Crystal Clean’s HCC 150 re-refined base oil product was found to have a GHG footprint 77% lower compared to virgin base oil. This study confirmed that re-refined base oils are a more sustainable alternative, both in virtue of reducing waste by recycling used oil, and through efficient operations to develop the re-refined product.

Promoting the Circular Economy Through Used Oil Re-Refining

Thanks to advancements in re-refining technology, oil can now be transformed into a renewable resource. Used oil re-refining has quickly become a reliable process to take used oil and transform it into a recyclable, renewable resource. With a state-of-the-art re-refinery capable of processing over 75 million gallons of used oil annually, Crystal Clean is an industry leader in sustainability.

Embracing re-refined base oil not only reduces greenhouse gas emissions but also positions businesses as leaders in sustainable innovation, setting an example for their industry and beyond. Crystal Clean remains committed to transforming oil into a renewable resource and re-refining used oil into new usable base oils and other co-products.

Partnering With The Oil and Lubricants Industry

Crystal Clean is a proud member of the Independent Lubricant Manufacturers Association (ILMA), ENFINITE: The Industrial Liquid Recyclers Association, the Asphalt Institute, and the Society of Tribologists and Lubrication Engineers (STLE). We strive to continually be at the forefront of cutting-edge innovations seen in oil re-refining.

Highlighted Industries

Crystal Clean’s Re-Refinery products are suited for a wide range of applications in a variety of industries, including:

Specialty Applications

Your business is unique, and you need the right environmental services designed for your needs. Crystal Clean offers the environmental services you can rely on to support your business.

Automotive

Crystal Clean’s comprehensive suite of environmental services make it the perfect partner for automotive businesses looking to have all their environmental services performed by one company.