July 23, 2024

Oil is one of the most commonly used substances in the world and it impacts everyone’s life in some way, whether it’s in their personal or professional life. As one of the primary lubricants used in machines, oil is used to literally keep our world running every day. But a common misconception about oil is that it not a renewable resource and that it must be disposed once it has been used. But that’s not true, and oil no longer has to be a non-renewable resource. Thanks to the advanced technology of oil re-refining, used oil can now be recycled and transformed into a renewable resource indefinitely.

What Type of Oil Is Used for Re-refining?

To better understand the recycling of used oil, we need to first understand what exactly qualifies as used oil for a re-refinery. These specific oil types are typical of engine and machine part lubricants. Examples include engine oil, synthetic engine oil, hydraulic oil, and gear oil. These lubricants are ideal candidates for re-refining due to their similar lubrication properties, with viscosity being the primary difference based on their specific applications. As they are used in an application, the oil begins to break down. This can result from heat and pressure over time or accumulating contaminants such as dirt and engine debris, resulting in a sludge. Once the oil begins to break down the additives in the oil that enhance its viscosity begin to diminish over time. At this point, whether it’s a 3,000 mile or a 10,000 mile oil change, the now used oil is ready to be collected and make its way to an oil re-refinery.

How is Used Oil Re-refined?

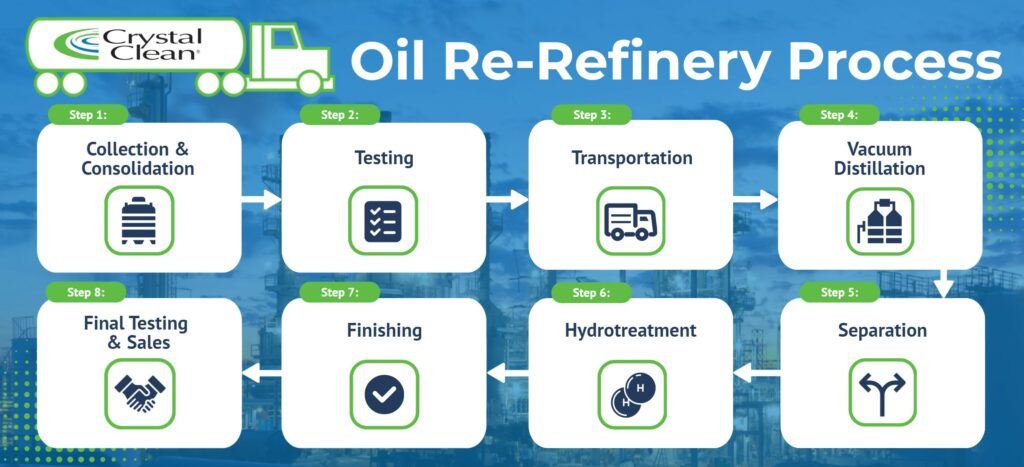

The re-refining process begins as soon as the used oil arrives at the facility. First, it goes through a set of rigorous tests to confirm it meets the requirements to become a useable base oil. Once all the boxes are checked, the used oil is pumped to the vacuum distillation unit. This unit heats the oil under vacuum, which lowers the boiling point and allows the oil to become vaporized. As this gas is produced, this in turn allows vacuum gas oil (VGO) vapor to be separated from the residue or vacuum tower asphalt extender (VTAE). The VGO vapor is condensed and cooled before being pumped to the hydro treatment. Different oil types are separated into three distinct products during this process dependent on the boiling temperature: vacuum gas oils (VGO), light distillate fuels (LDF), and vacuum tower asphalt extender (VTAE). Each of these products go to a different part of the facility to start a separate journey to become a usable product.

Vacuum gas oils undergo further re-refining to become base oil through a process called hydrotreatment. During hydrotreatment, the VGO is treated with hydrogen gas at high temperatures and pressures to remove contaminants. The hydrogen reacts with the impurities, converting them into stable compounds that can be separated and removed. The result is a cleaner, higher-quality base oil that can be further processed into lubricants or other valuable products. Hydrotreatment is essential for ensuring that the recycled oil meets strict quality standards and can effectively replace virgin oil in various applications. Light distillate fuels collected during the distillation process possess unique properties that make them an excellent sustainable energy source. The vacuum tower asphalt extender can be found remaining at the bottom of the vacuum distillation unit. It has many useful properties such as flexibility, waterproofing, and adhesion that make it an ideal binding agent for producing roofing shingles and asphalt pavement.

Re-refining is the sustainable way to manage used oil. By recycling used oil at Crystal Clean’s re-refinery, we make oil into a renewable resource, creating a variety of new base oils and materials used to construct homes and roads in local communities. This transformation not only showcases the innovative potential of re-refining but also highlights the significant environmental and economic benefits of recycling used oil.

For more information about Crystal Clean’s re-refining process and products, visit here.