December 1, 2025

Industrial facilities rely on heat transfer fluids (HTFs) to manage temperature, protect equipment, and maintain operational continuity across a wide range of environments. Whether supporting HVAC loops, stationary engines, process equipment, or seasonal shutdowns, using the proper fluid is essential for system longevity and performance.

Unlike automotive coolant, industrial HTFs must accommodate diverse operating temperatures, metallurgy, system pressures, and environmental considerations. Additive packages, glycol type, inhibitor chemistries, and OEM requirements all influence which product best fits the application. Selecting the appropriate fluid helps prevent corrosion, scaling, fouling, freeze damage, and costly equipment failures.

Below is an overview of Crystal Clean’s industrial heat transfer fluid portfolio and where each product delivers its best performance.

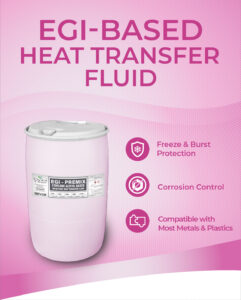

Ethylene Glycol–Based Industrial HTF (EGI-HTF)

Best for: Commercial and industrial systems requiring a high-phosphate, multi-metal corrosion-protected ethylene glycol fluid.

Key Benefits: EGI-HTF uses a robust high-phosphate inhibitor system that provides excellent protection for copper, brass, solder, steel, cast iron, and aluminum. The formulation prevents scaling, fouling, and pH degradation while delivering reliable thermal performance across an operating range of –60°F to +300°F. It is functionally equivalent to DOWTHERM™ and JEFFCOOL® E100, allowing seamless top-offs or changeovers, and is available in both concentrate and ready-to-use premix options for easy implementation.

Where It Fits: Ideal for a wide range of industrial temperature-control applications including HVAC systems, solar heating, process loops, thermal storage, ice rinks, sidewalk melting, floor heating, and cold-room dehumidification.

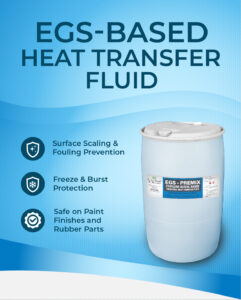

Ethylene Glycol–Based Stationary Engine HTF (EGS)

Best for: Heavy-duty stationary engines requiring nitrited protection and OEM-aligned performance.

Key Benefits: EGS features an advanced inhibitor system with a minimum of 2400 ppm nitrite in concentrate, delivering superior protection against cavitation, hot-surface scaling, and corrosion in wet-sleeve liners, water pumps, and mixed-metal systems. The silicate-free, phosphate-free formulation minimizes deposits while meeting ASTM D6210, D4985, D3306, and D1384 performance standards. It provides year-round defense against freeze-ups, boil-overs, and coolant breakdown, making it a reliable solution for demanding stationary engine environments.

Where It Fits: Designed for oil & gas, natural gas processing, compressor engines, power generation, and other industrial stationary engines. Suitable for use in systems calling for Cummins CES14603, Caterpillar DEAC, John Deere H24, Waukesha 4-1974D, EMD 1748E, and related OEM specifications.

Propylene Glycol–Based Industrial HTF (PGI-HTF)

Best for: Industrial systems needing lower toxicity, high-phosphate inhibitors, and full corrosion protection across wide temperature ranges.

Key Benefits: PGI-HTF combines a propylene glycol base with a high-phosphate, multi-component inhibitor package to deliver excellent corrosion resistance and thermal stability. The reduced toxicity allows for safer handling and disposal, while the formulation protects copper, brass, solder, steel, cast iron, and aluminum from rust, scaling, and acidic attack. With an operating range from –60°F to +300°F and compatibility with DOWFROST HD™ and JEFFCOOL® P150, it provides broad system compatibility and long-term reliability.

Where It Fits: A strong choice for HVAC systems, solar heating, floor heating, thermal storage, ice rinks, sidewalk snow-melting systems, process cooling/heating, and cold-room dehumidification.

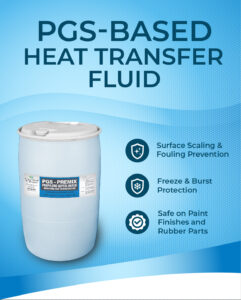

Propylene Glycol–Based Stationary Engine HTF (PGS)

Best for: Stationary engines requiring heavy-duty inhibitors and lower-toxicity glycol bases.

Key Benefits: PGS delivers the same heavy-duty performance expected in stationary engine environments while leveraging a propylene glycol base for reduced toxicity. Its nitrited, silicate-free, and phosphate-free formulation protects wet-sleeve liners from cavitation, shields all system metals from corrosion, prevents hot-surface scaling, and disperses minor oil leakage. Meeting ASTM D6210, D4985, D3306, and D1384 requirements, it maintains dependable freeze, boil-over, and corrosion protection year-round.

Where It Fits: Recommended for oil & gas compression, energy production, natural gas processing, and industrial engine applications requiring OEM standards such as Cummins, Caterpillar, John Deere, Waukesha, and EMD.

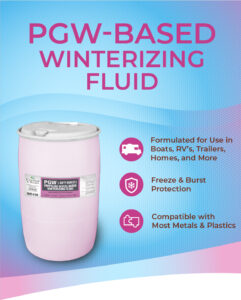

Propylene Glycol–Based Winterizing Fluid (PGW)

Best for: Seasonal shutdowns requiring burst protection for potable water systems, HVAC loops, and recreational equipment.

Key Benefits: PGW is a ready-to-use winterizing solution available in –50°F and –100°F burst protection formulas, using a phosphate-based corrosion inhibitor to protect metals such as copper and brass. Dyed pink or blue for easy system verification, it is safe for most plastics and can be mixed with comparable RV and marine winterizing fluids without adverse effects. Its formulation prevents freeze expansion damage in systems exposed to severe temperatures, providing reliable seasonal protection.

Where It Fits: Ideal for winterizing boats, RVs, trailers, vacation homes, swimming pool filtration systems, and commercial or residential water loops requiring seasonal shutdown.

Matching Products to Industrial Performance and Protection

Choosing the right heat transfer fluid is more than meeting performance specifications—it protects critical equipment, optimizes operational efficiency, prevents unplanned downtime, and simplifies inventory management. Crystal Clean offers an industrial-grade portfolio engineered for superior thermal performance, corrosion resistance, and long-term system reliability.

With high-quality fluids, nationwide supply capability, and closed-loop recycling services for used glycol, Crystal Clean helps industrial operators reduce waste, lower disposal costs, and maintain safe, efficient, and environmentally responsible systems year-round.